3pcs 굴착 스핀들 CNC H/I 빔 굴착 및 절단 기계 100~600mm 높이 범위

생산 라인의 목적:

이 생산 라인은 주로 굴착, 표시,그리고 H 빔과 채널 스틸과 같은 모양의 철강에 대한 프레싱 작업, 브릿지 엔지니어링, 그리고 중용 장비 제조. 이 핵심 처리 작업을 고밀도로 처리하도록 설계되었습니다.완성된 모양의 강철이 산업용 용도의 엄격한 차원 및 구조 요구 사항을 충족시키는 것.

주요S사양:

| 매개 변수 |

가치 |

| 작업 조각 크기 |

너비 범위 |

150~1250mm |

| 높이 범위 |

100~600mm |

| 원료의 길이 범위 |

2000~12000mm |

| 완성된 작업 조각의 길이 범위 |

2000~12000mm |

| 부착 스핀들 |

굴착 스핀드 수 |

3 |

| 스핀드 뚫기 톱니 |

BT2 |

| 스핀드 모터 파워 |

11kW |

| 회전 속도 |

200~3000 r/min |

| 굴착 지름 범위 |

φ5~φ30 |

| CNC 축 |

X축 서보 모터 전력 |

약 4.4kW |

| X축 최대속도 |

40m/min |

| 수평 포지셔닝 축을 뚫기 위한 세르보 모터 전력 |

약 1.5kW |

| 수평 포지셔닝 축을 뚫는 최대 속도 |

10m/min |

| 굴착 수평 공급 축의 서보 모터 전력 |

약 2kW |

| 수평 포지셔닝 축을 뚫는 최대 속도 |

10m/min |

| 굴착 수직 위치 축 서보 모터 전력 |

약 3kW |

| 굴착 수직 위치 축의 최대 속도 |

10m/min |

| 굴착 수직 공급 축 서보 모터 전력 |

약 3kW |

| 굴착 수직 공급 축의 최대 속도 |

10m/min |

| 도구 잡지 |

양 |

3 세트 |

| 종류 |

직선형 |

| 도구량 |

4 x 3 |

| 수압 표시 장치 |

문자 수 |

36 |

| 문자 크기 |

Φ10 |

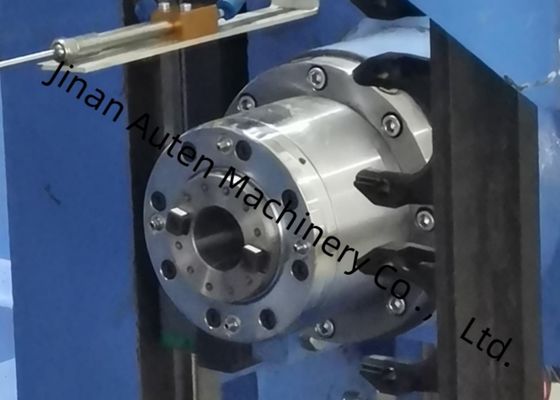

굴착기에는 3개의 BT40 고속 스핀드가 장착되어 있으며, 이 스핀드는 각 면에 한 개의 스핀드가 있는 철제 작업재의 세 면에 대한 굴착 작업을 수행하는 데 사용됩니다.해당 줄형 도구 매거진은 최대 4 개의 도구 사양을 수용합니다.이 호스트는 CAD 도면을 가공 프로그램으로 변환하는 것을 지원합니다. 또한 여러 스레드 동기 작동을 가능하게하며, 파도와 같은 작업의 합리적인 스케줄링을 허용합니다.작업 부품 이동, 도구 변경 및 스핀드 위치. 이것은 두 개 또는 세 가지 작업을 동시에 완료 할 수 있으며 생산 효율성을 크게 향상시킵니다.

부품:

이 생산 라인은 주로 로딩 수평 재료 테이블, 3D 드릴링 주 기계, 3D 드릴링 공급 채널, 3D 드릴링 공급 장치, 3D 드릴링 배charge 채널,냉각 시스템, 수압 시스템, 공기 시스템, 윤활 시스템, 전기 시스템 및 기타 관련 구성 요소. 생산 라인은 고정 된 침대와 이동 작업 조각 구조를 채택합니다.자동화 된 생산 프로세스를 효과적으로 촉진하고 연속 가공 중에 안정적인 작동을 보장합니다..

1로딩 수평물질 테이블

이 구성 요소는 재료 테이블 브래킷, 컨베이어 체인, 기어 모터 및 기타 관련 부품으로 구성되어 있으며, 철근 작업 부품을 공급 채널로 전달하도록 설계되었습니다.로딩 수평 재료 테이블은 고객이 구입 한 직렬 기계에 연결됩니다., 고객의 기존 생산 작업 흐름에 원활한 통합을 보장합니다.

23차원 뚫기 공급 채널

3차원 굴착 공급 채널은 고객 현장에서 직렬 기계와 연결하기 위해 전력 롤러를 채택합니다.그것은 곧게 프로파일을 수신하고 자동으로 먹이 트롤리의 클램프 위치에 전달이 구성에서, 바닥에서 롤러의 상위 평면의 높이는 800mm로 설정됩니다. 곧게하는 기계가 다른 높이를 가지고 있다면, 사용자는 그에 따른 조정을 수행해야합니다.공급 채널은 처리 될 작업 조각을 지원하도록 설계되었습니다.광 전기 스위치가 채널 앞 끝에 설치되어 작업 조각의 앞쪽 끝을 감지하여 X 방향 처리 참조를 결정합니다.측면 밀기 장치 작업 조각을 단단히 클램프하고 측면 위치 롤러에 그것을 압박, Y 방향으로 작업 조각의 거친 위치 실현.

예를 들어, 샘플 시범 세션에서는 the machine tool can effectively showcase its machining capabilities through standard H-beam samples (featuring varied flange widths and web thicknesses) and channel steel samples of different dimensions이 전시된 표본은 정밀한 구멍 위치, 부드러운 탭 스레드,그리고 명확한 표시 패턴은 실제 응용 시나리오에서 높은 정확성과 신뢰성을 완벽하게 반영합니다..

고속 CNC H 빔 굴착 기계는 주로 철강 구조 작업실 및 다리 건설 프로젝트에 배치됩니다. 철강 구조 작업실 내에서,프레임 및 지원 구조에 사용되는 H 빔에 정밀 가공을 수행합니다., 따라서 강철 구조물의 안정적인 조립에 대한 견고한 기반을 구축합니다.H 빔에 높은 정확도의 드릴 작업을 수행합니다. 이것은 다리의 구조적 무결성을 향상시키는 데 기여합니다., 장시간의 부하에 견딜 수 있도록 해줍니다. 높은 운영 효율은 이러한 핵심 인프라 부문에 대한 신뢰할 수있는 기술 지원을 제공합니다.프로젝트 실행의 원활한 진행을 보장.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!